Description

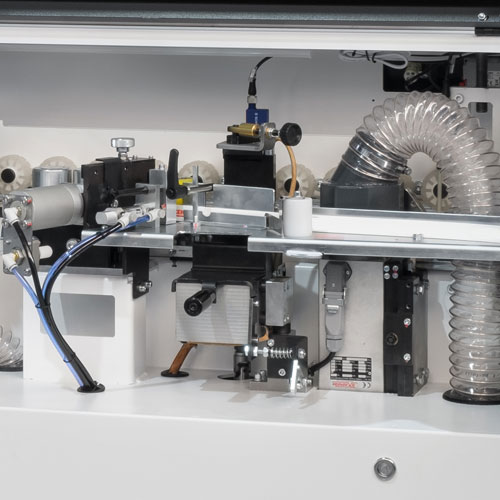

Pre-milling in a small footprint

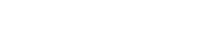

- Edge Tape: 0.4-2 mm

- Panel Thickness: 10-40mm

- 1 Phase 220V 60Hz

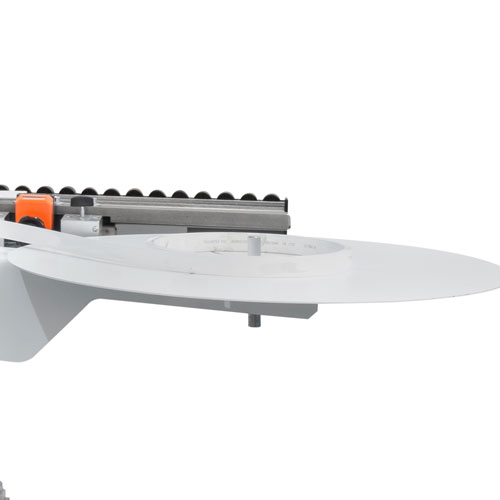

- Glue Scraper Unit

- Buffing Unit

- End Trimming HF Motor

- Pre-milling Unit 1 HF Motors

- Glue Pot Capacity 0.5kg | 1lbs Teflon Coated

- Automatic feeding Speed 21 ft/min

- Net Weight 1146 Lbs | 520 kgs

- Compact Design

- Melamine/PVC/ABS/PP

| CBC.TPM | SAE | METRIC |

|---|---|---|

| Automatic Feeding speed | 21 ft/min | 6.5 m/min |

| Panel thickness Min/Max | – | 10 – 40 mm |

| Max Pre-milling Height | 1” | 30 mm |

| Edgebanding thickness | 0.0157″ – 0.07″ | 0.4-2mm |

| Glue Pot Capacity | 1lbs | 0.5 kg |

| Max Edgebanding Height | 1″ | 30 mm |

| Minimum panel width | 4 3/4″ | 120 mm |

| Minimum panel length | 7 7/8″ | 200 mm |

| Extendable Panel Support Rail Length | 83 1/2″ | 2122 mm |

| Extension table Max Width | 10″ | 257 mm |

| Size of Dust Collector Ports | 5″ | 127mm |

| Minimum Dust Collection Requirements | 1236 CFM | 2100 m3/h |

| Air Pressure Requirement | 7 SCFM @ 90 PSI | 0.7 Mpa 200 L/min |

| Edgebanding coil Support Diameter | 59″ | 1498 mm |

| Recommended Glue Temperature Range | 356°F – 410°F | 180°C – 210°C |

| Max. machine dimensions (LxWxH) | 93 1/2”x 40 13/16”x 53” | 2376 x 1028 x 1347 mm |

| Net weight | 1146 LBS | 520 KGS |

| Shipping dimensions (LxWxH) | 91” x 30” x 57” | 2320 x 760 x 1448 mm |

| Glue Type | Granulated Hot-Melt EVA | Granulated Hot-Melt EVA |

| Electrical Information | 1 Phase 220V 30 Amps 60Hz | 1 Phase 220V 30 Amps 60Hz |

| Sound Rating | 80 dB | 80 dB |

| Motor/Electrical | Specs |

|---|---|

| Electrical Requirement | 1 Phase 220V 30 Amps 60 Hz |

| Conveyer Motor | 60 Hz 1390 RPM .66 kw |

| Top/Bottom Trimmer HFM | 200 Hz 12,000 RPM .27kw |

| End Trimmer Motor | 200 Hz 12,000 RPM .27kw |

| Front/Rear Pre-Milling HFM | 150 Hz 9000 RPM .75/.25Kw |

| Top Buffing Motor | 60 Hz 1680 RPM .11kw |

| Bottom Buffing Motor | 60 Hz 1680 RPM .11kw |

| Sound Rating | 80 dB |

| Technical Info | CBC Flex | CBC.E | CBC.MR | CBC/2.MR | CBC.T | CBC.TPM | CBC.PCR |

|---|---|---|---|---|---|---|---|

| Eletrical specs | 1 Phase 110V 550W 60Hz | 1 Phase 110V 1500W 60Hz | 1 Phase 110V 1500W 60Hz | 1 Phase 110V 1500W 60Hz | 1 Phase 220V 60Hz 30A | 1 Phase 220V 60Hz 30A | 1 Phase 220V 60Hz 30A |

| Feeder Speed | 0-19 ft/min | 0-18 ft/min | 0-26 ft/min | 0-26 ft/min | 0-16ft/min | 21ft/min | 18ft/min |

| Edgebanding Thickness | 0.4 – 1mm | 0.4 – 2mm | 0.4 – 2mm | 0.3 – 2mm | 0.4 – 3mm | 0.4 – 2mm | 0.4 – 3mm |

| Glue Temperature | 130° to 180° C | 130° to 180° C | 130° to 180° C | 130° to 180° C | 180° to 210° C | 180° to 210° C | 180° to 210° C |

| Glue Pot Type | Low Temp. Granulated Hot-Melt EVA | Low Temp. Granulated Hot-Melt EVA | Low Temp. Granulated Hot-Melt EVA | Low Temp. Granulated Hot-Melt EVA | High Temp. Granulated Hot-Melt EVA | Granulated Hot-Melt EVA | Granulated Hot-Melt EVA / PUR |

| Workarea | – | 39 3/8″ x 15 3/4″ | 101 3/4″ x 15 3/4″ | 101 3/4″ x 15 3/4″ | 78 3/4″ x 10 2/5″ | 93 1/2″ x 41″ | 119″x40″ |

| Max Edgebanding Height | 1/2″ to 1 7/8″ | 3″ | 3″ | 3″ | 2″ | 1″ | 2″ |

| Panel Thickness | 1/2″ to 1 7/8″ | 3″ | 3″ | 3″ | 12-45mm | 10-40mm | 8-50mm |

| Weight | 21 Lbs | 114 Lbs | 242.5 Lbs | 330 lbs | 1025 Lbs | 1146 Lbs | 1653 Lbs |

| Machine Dimension | 11″ x 14″ x 13 1/2″ | 47″ x 31″ x 42″ | 101 3/4″ x 35 1/2 x 43″ | (101 3/4″) 58″ x 43″ x 43″ | 112″ x 63″ x 51″ | 93. 1/2″ x 41″ x 53″ | 119″ x 41″ x 49″ |

| End Trim | – | Manual | Manual | Manual | Pneumatic | Pneumatic | Pneumatic |

Instructions

Download the Manual

The Glue Recommendation

Download The Glue Recommendation