Description

Our new CBC.T is already one of our customers favorite!

- Machine frame made out of steel, single block base with superior stability.

- Anodized aluminum outfeed fence.

- 1 Phase 220V

- Table Dimension 2000 mm x 265 mm

- Tape Thicness 0.4 mm to 3 mm

- Panel Thicness 12mm / 45mm

- Automatic Panel Feed System

- Dual Pressure rollers

- Melamine, PVC, ABS, PP, Veneer, Solid Wood Strip and Laminate

- Pre-Heated Infeed Fence

- Indivudually adjustable Flush Trimming

- Digital Temperature Control

- Pre-heated infeed fence

- Front and back end Trimming

- Top and Bottom Flush Trimming

- Dual Buffing Unit

- Extendable Panel Support Rail

- Push button Control panel

- 2 Warranty

MACHINE PERFORMANCE

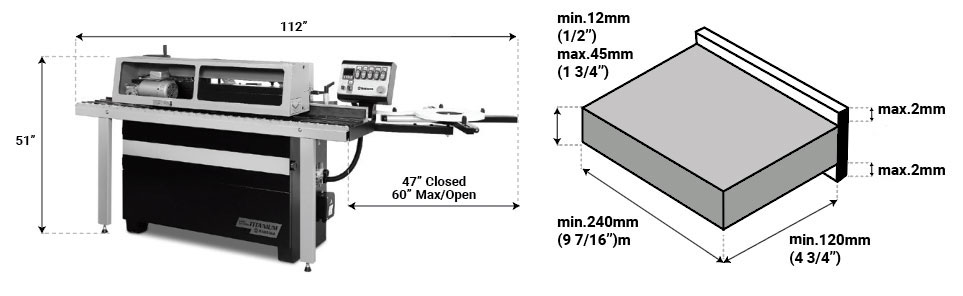

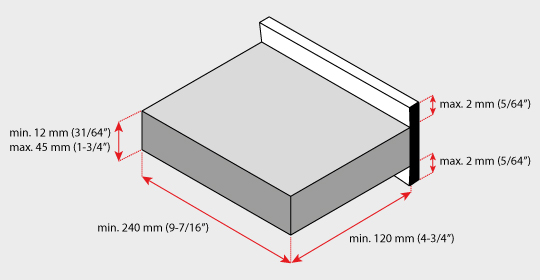

The Maksiwa Titanium Automatic Edgebander CBC.T is incredibly versatile, it handles panels up to 45mm thick, automatic feed and spread glue directly on the workpiece and can be adjusted to use edge tape between a thickness of 0.4 and 3 mm.

PANEL CONTROL

Located on the front of the machine in an ergonomic position. This unit is used to control all of the machine’s functions quickly and intuitively. There you can see and adjust the Digital Glue Temperature Control – shows the desired and current temperature; activate pre-heating and glue pot heating, glue spindle, conveyor belt, front/rear trimming, top/down trimming, and buffing unit.

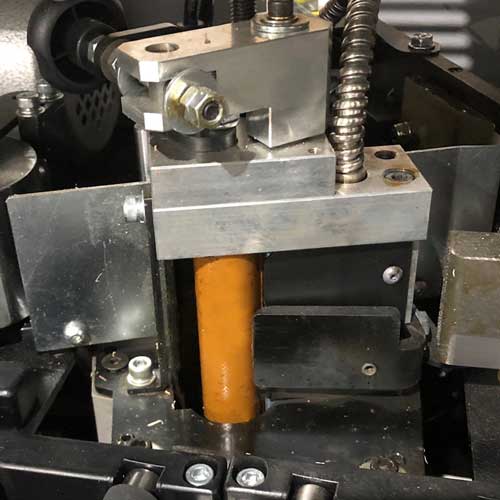

GLUE POT UNIT

The glue pot unit is heated rapidly and evenly to maintain the optimal temperature. With 2 lbs capacity. Proper glue should have an average temperature between 180° to 210° Celsius and be pellet glue.

CONVEYOR BELT

With a movement system designed for a perfect finish, moves the panels to be edge through the machine smoothly, providing the very best finish.

FRONT/REAR TRIMMING

The glue pot unit is heated rapidly and evenly to maintain the optimal temperature. This is made easy by using the Digital Control, once set it keeps the temperature constant unless in “stand-by” mode which lowers the temperature without turning off the machine, the glue spindle has two pressure rollers allowing the glue to be spread evenly to the panel.

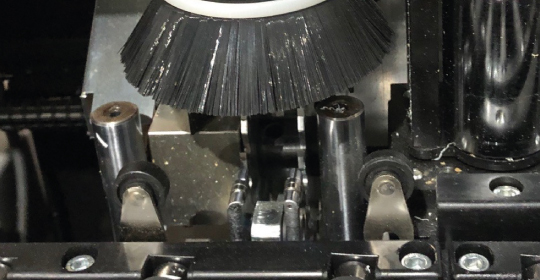

BUFFING UNIT

The buffing unit is designed to polish edges and maintain their natural colors. Two independent buffing wheels for cleaning and polishing can be adjusted to a particular angle to maximize its effect for better workpiece finishing and extending buffing wheel service life.

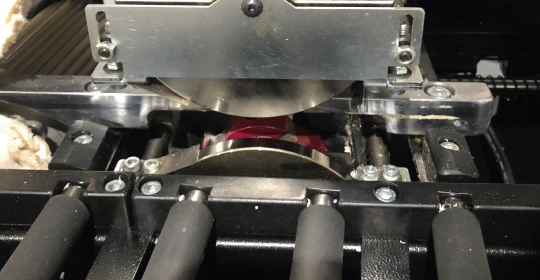

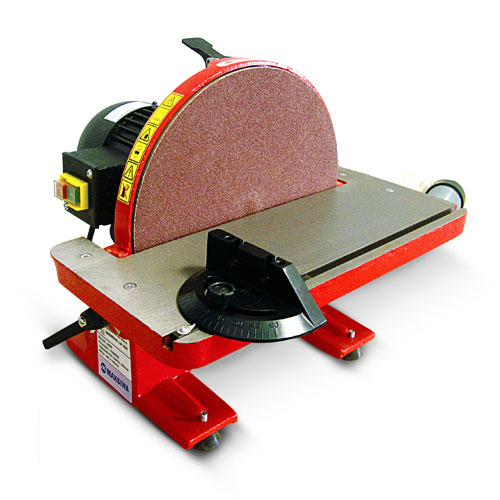

TOP/BOTTOM TRIMMING

The top/bottom trimming units are automatic and manually adjustable. These trimmers consist of high-polish chrome plated copy shoes which ensure a smooth and accurate profile.

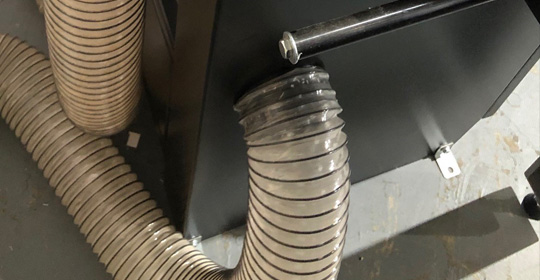

DUST COLLECTION

Equiped with 2 dust collection ports 4″/100mm.

| CBC.T SPECIFICATIONS | SAE | METRIC |

|---|---|---|

| Automatic Feeding speed | 16ft/MIN | 5M/MIN |

| Panel thickness Min/Max | 31/64″ – 1 3/4″ | 12 – 45 MM |

| Edgebanding thickness | 0.0157″ – 0.118″ | 0.4 – 3 MM |

| Glue Pot Capacity | 2 Lbs | 1 kg |

| Max Edgebanding Height | 2″ | 50 MM |

| Minimum panel width | 4 3/4″ | 120 MM |

| Minimum panel length | 9 7/16″ | 240 MM |

| Extendable Panel Support Rail Length | 78 21/32″ | 1998 MM |

| Extension table Max Width | 12″ | 310 MM |

| Size of Dust Collector Ports (2) | 4″ | 100 MM |

| Minimum Dust Collection Requirements | 700 CFM | 20M/MIN |

| Air Pressure Requirement | 6 SCFM @ 100 PSI | 7 kg/cm2 |

| Edgebanding coil Support Diameter | 31 1/2″ | 820 MM |

| Recommend Glue Temperature Range | 356°F – 410°F | 180°C – 210°C |

| Glue Type | Pellet – Granulated Hot-Melt | Pellet – Granulated Hot-Melt |

| Max. machine dimensions (LxWxH) | 112″x 63″x 51″ | 2844 x 1600 x 1295 MM |

| Machine weight | 849 LBS | 385 KGS |

| Shipping dimensions (LxWxH) | 86″ x 36″ x 57″ | 2184 x 914 x 1448 MM |

| Shipping weight | 1025 Lbs | 465 Kgs |

| Motor/Electrical | Specs |

|---|---|

| Electrical Requirement | 1 Phase 220V 30 Amps 60 Hz |

| Conveyer Motor | 3/4HP(0.55KW) |

| Flush Trimmer Motor | 3/4HP(0.55KW) |

| End Trimmer Motor | 1/4HP(0.18KW) |

| Glue Spindle Motor | 1/3HP(0.25KW) |

| Top Buffing Motor | 1/4HP(0.18KW) |

| Bottom Buffing Motor | 1/4HP(0.18KW) |

| Sound Rating | 80 dB |

| Technical Info | CBC Flex | CBC.E | CBC.MR | CBC/2.MR | CBC.T | CBC.P |

|---|---|---|---|---|---|---|

| Eletrical specs | 1 Phase 110V 550W 60Hz | 1 Phase 110V 1500W 60Hz | 1 Phase 110V 1500W 60Hz | 1 Phase 110V 1500W 60Hz | 1 Phase 220V 60Hz 30A | 1 Phase 220V 60Hz 30A |

| Feeder Speed | 0-19 ft/min | 0-18 ft/min | 0-26 ft/min | 0-26 ft/min | 0-16ft/min | 23ft/min |

| Edgebanding Thickness | 0.4 – 1mm | 0.4 – 2mm | 0.4 – 2mm | 0.3 – 2mm | 0.4 – 3mm | 0.4 – 3mm |

| Glue Temperature | 130° to 180° C | 130° to 180° C | 130° to 180° C | 130° to 180° C | 180° to 210° C | 180° to 210° C |

| Glue Pot Type | Low Temp. Granulated Hot-Melt EVA | Low Temp. Granulated Hot-Melt EVA | Low Temp. Granulated Hot-Melt EVA | Low Temp. Granulated Hot-Melt EVA | High Temp. Granulated Hot-Melt EVA | Granulated Hot-Melt EVA / PUR |

| Workarea | – | 39 3/8″ x 15 3/4″ | 101 3/4″ x 15 3/4″ | 101 3/4″ x 15 3/4″ | 78 3/4″ x 10 2/5″ | 112″x34″ |

| Max Edgebanding Height | 1/2″ to 1 7/8″ | 3″ | 3″ | 3″ | 2″ | 2″ |

| Panel Thickness | 1/2″ to 1 7/8″ | 3″ | 3″ | 3″ | 12-45mm | 10-50mm |

| Weight | 21 Lbs | 114 Lbs | 242.5 Lbs | 330 lbs | 1025 Lbs | 1719 Lbs |

| Machine Dimension | 11″ x 14″ x 13 1/2″ | 47″ x 31″ x 42″ | 101 3/4″ x 35 1/2 x 43″ | (101 3/4″) 58″ x 43″ x 43″ | 112″ x 63″ x 51″ | 112″ x 156″ x 49″ |

| End Trim | – | Manual | Manual | Manual | Pneumatic | Pneumatic |

Instructions

Download the Manual

The Glue Recommendation

Download The Glue Recommendation

Reviews

There are no reviews yet.